Target minus 30% by 2030

Our brand has set itself the target of reducing its environmental impact by 30% for each pair of skis produced by 2030. This is the challenge we have set ourselves for the next 10 years as part of the ZAGreen program.

Indeed, based on our 2019 impact, we found that the production of a pair of skis produces an average of 116kgCO2eq.

By 2030, our aim is to reduce this figure to an average of 80kgCO2eq per pair of skis, i.e. an impact reduced by 30% over 10 years.

As ZAG is a growing company, we have decided to focus on the impact of our peers rather than that of the company as a whole. Nevertheless, we aim to control the impact of our growth and, consequently, to reduce it in relation to our products.

In our view, this 30% project is 100% feasible. We believe in our ability to reach this target, and even exceed it, in order to reduce the impact even further.

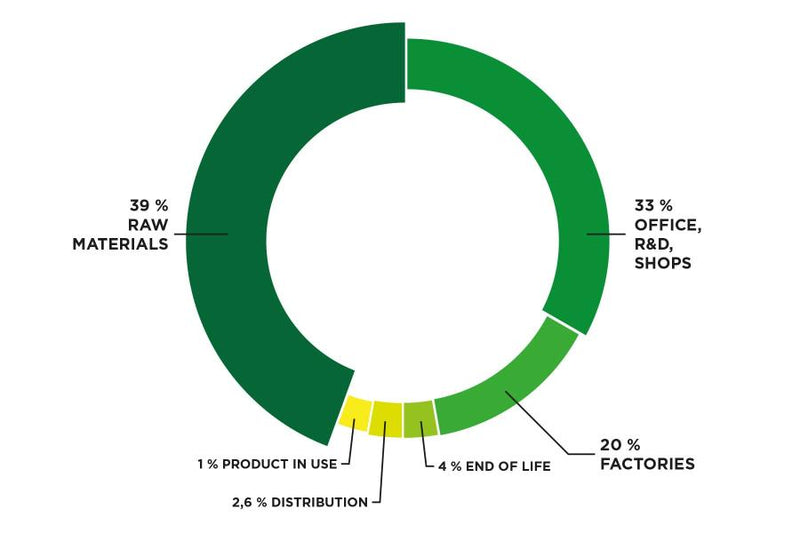

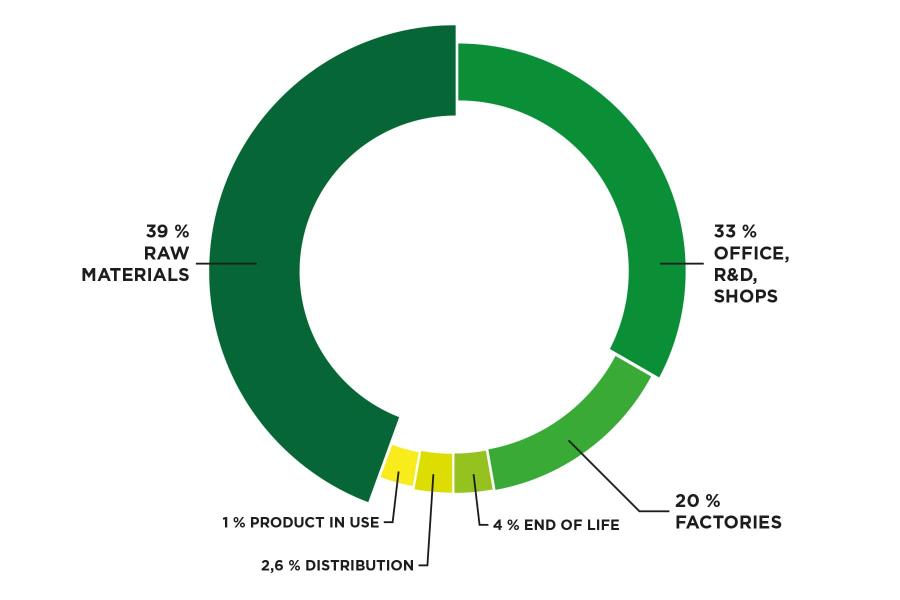

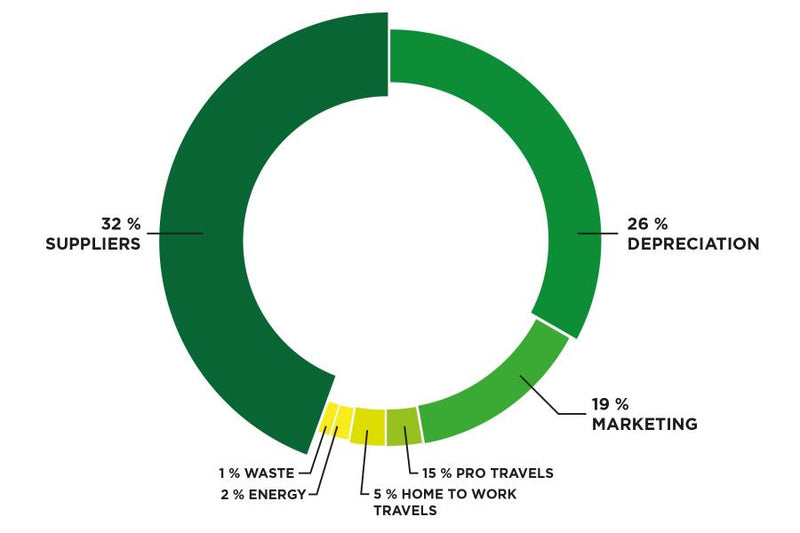

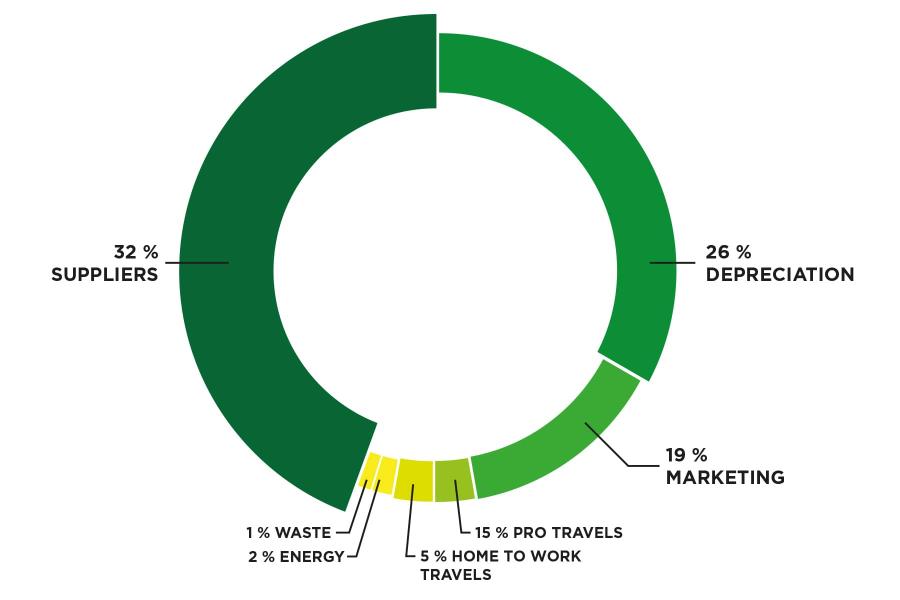

Our current carbon footprint VS 2030 target

After a study of our carbon impact, we found that the 3 main sources for ZAG are: raw materials, headquarters/offices/ZAG Lab and factories. So we're going to focus on these three main areas.

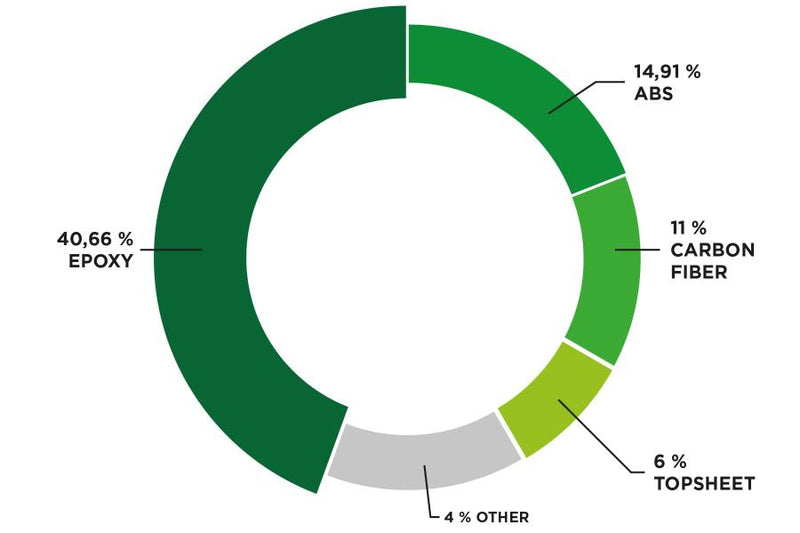

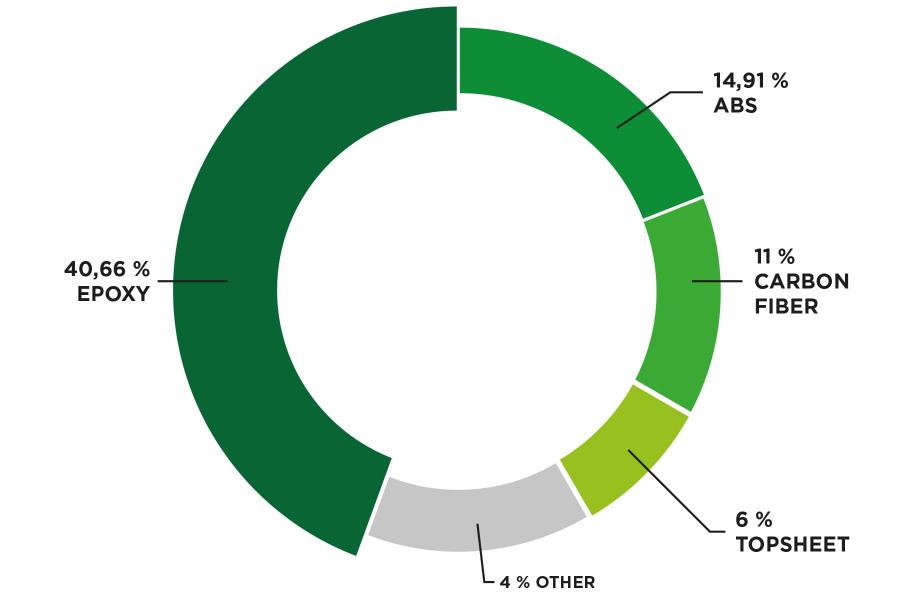

Raw materials

Our first impact is everything we use in the skis, skins and Bindings we sell.

As regards seal skins and Bindings (which represent 44% of the total impact of raw materials), we will continue to work with companies committed to the environmental cause, with values that match our own. The POMOCA brand, for example, produces our seal skins not far from our mountains, above Lausanne, and is in line with our ecological approach.

1. Epoxy resin : the most impacting raw material (40%). Today, we also use 33% and 25% biobased resins, in small quantities. In equal quantities, this resin has 40% less impact than its compatriot, epoxy resin.

2030 objective: convert all our skis to 33% biosourced resin, and use at least 50% of this biosourced resin for a significant proportion of production.

2. ABS : 2nd most impactful material, but miles ahead of epoxy resin.

Objective 2030: find a more responsible alternative.

3. Carbon fiber : an impact of 11% for only 1% in quantity in the total impact of raw materials.

Objective 2030: A complicated material to replace, we are currently working on substitutes to bring you Touring skis that are as light and high-performance as ever.

4. Topsheet: Big impact in relation to the quantity used.

Objective 2030: today, we're waiting for test feedback to see if the solution we've devised is sustainable over time.

Energy and plants

20% of our carbon impact is generated by our factories, particularly in the processing of raw materials.

Because we aim to produce mainly in Europe (90%), our partner factories are located in Poland and Tunisia. It should be noted that there are a limited number of factories in Europe, all of which are heavily used. On our scale, therefore, it's complicated to monitor the impact of our factories.

Objective 2030: our aim is for our current partners to be able to produce between 20% and 40% of their energy using clean, more environmentally-friendly means than the current large-scale solutions used in their respective countries (installation of solar panels, recovery of wood chips for heating, closed water circuits, etc.).

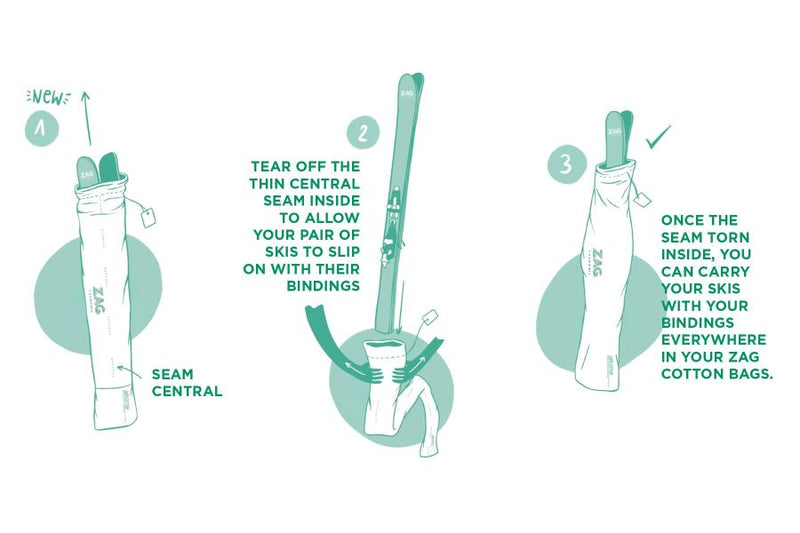

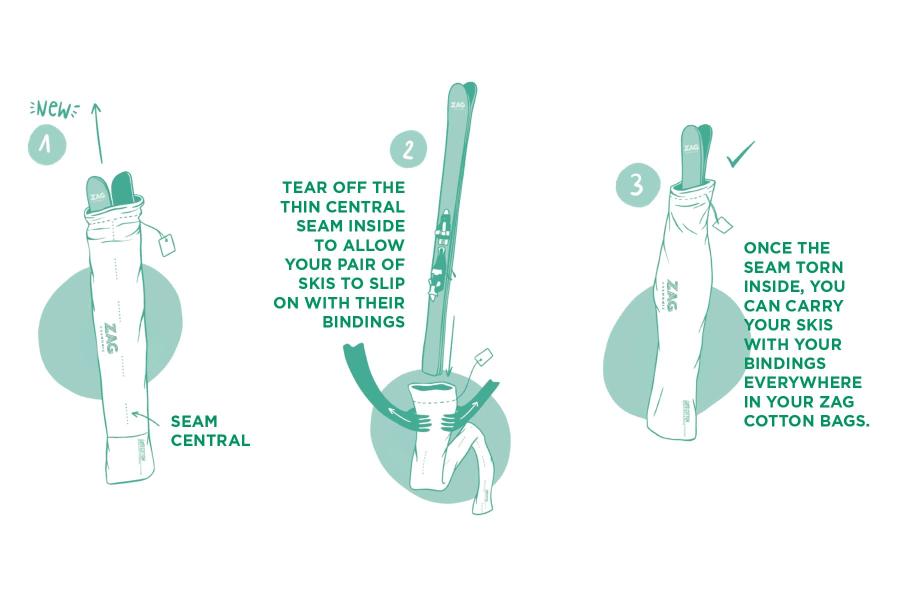

Plastic blisters : This is the plastic packaging that holds your new skis. We've already made progress in this area, as our skis are now packaged in reusable pouches that can be used as protective covers and/or fabrics for anything you can imagine and make.

Objective 2030: find an even more environmentally-friendly solution, in particular through material sourcing.

Soles: For the 23/24 season, we launched an 85% recycled base , made from scraps from the manufacture of other soles from our suppliers. It concerns the HARFANG and UBAC ranges.

Objective 2030: GOAL ACHIEVED - Produce 50% of our production with a recycled base

Infrastructure and premises

Our biggest impact comes from supplier expenditure, i.e. all the physical or intangible products we buy so that the company can carry out its business. In order to reduce this impact, our objective for 2030 will be to rationalize these purchases and focus on companies that share our convictions.

It's not in this sector that the biggest impact gains will be made, even if measures are planned, such as teleworking 3 days a week (for all possible positions) or streamlining our digital and marketing actions.