ZAGreen program

As skiers and outdoor enthusiasts, we share with you a deep respect for the wild, untamed nature of the mountains, as well as the joy they bring us. In the face of climate challenges that threaten this playground, we feel responsible for its preservation. That’s why we are committed to minimizing the impact of our activities on the climate and nature, while creating a positive local impact in Chamonix and the Alps. Taking care of our environment today, so we can ski more tomorrow!

ECO-DESIGN

Carefully selected materials

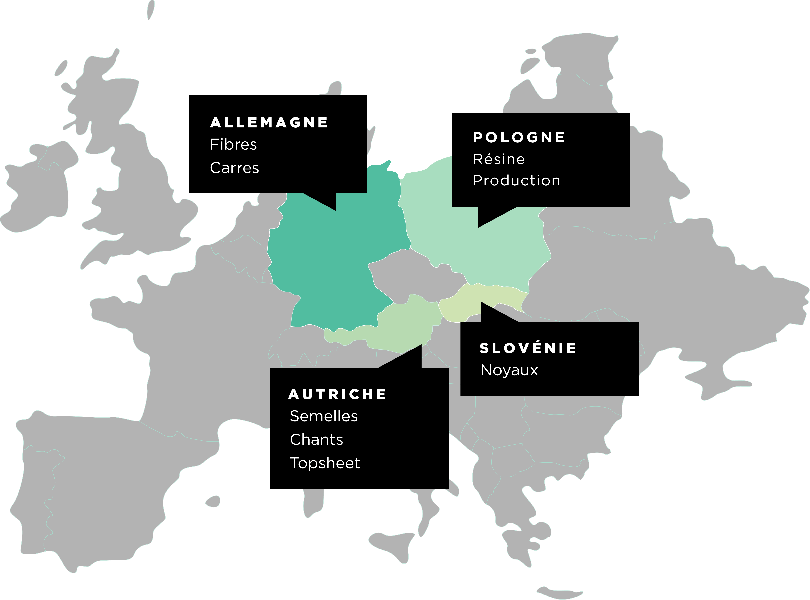

Since launching the ZAGREEN program in September 2015, we've focused on optimizing our supply chain by sourcing materials closer to our manufacturing sites in Poland and Tunisia. As a result, the components used in our skis now come primarily from European sources. At the same time, our R&D team is continually exploring materials that offer both high performance and a lower environmental impact.

Bio-sourced resin

We use 33% bio-sourced resin in our skis produced in Tunisia by the Meditec factory. These are the Adret and SLAP Junior models. This bio-sourced resin has been used since 2016. It is mainly derived from oilseed plants.

Objective:

Our goal is to implement this resin across the rest of our ranges. We are currently conducting laboratory tests to verify that this resin is compatible with all the materials we use. These validation tests are necessary to ensure that the quality of all our products is maintained. We are also working on bio-based resins with higher percentages.

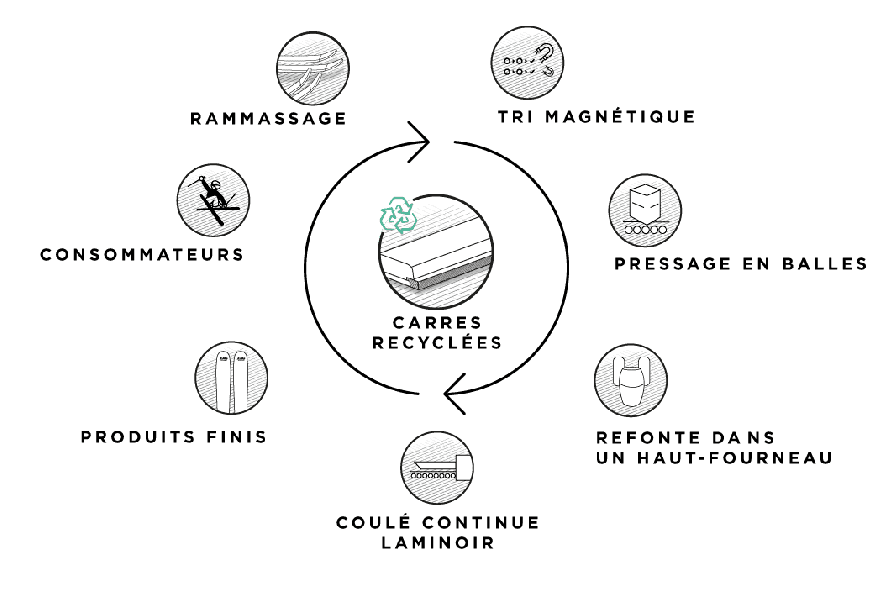

Recycled edges

All the edges we use at ZAG, whether thick on alpine skis or thin on ultra-light skis, are made from recycled metal.

BIO-SOURCED TOPSHEET

The topsheet is the decorative plastic surface that appears on the top of the ski. It protects against edge damage and other snags. Our topsheet is made from 50% bio-sourced polyamide derived from castor oil (a tropical shrub).

FIBRE

Fiber is the second most carbon-intensive material in a ski. We currently use a variety of glass, carbon and Kevlar fibers. These fibers are not natural, which is why we are working on sourcing fibers that are less harmful to the environment, such as flax, which reacts very well to vibration absorption.

ECO-RESPONSIBILITY

Tangible human actions

In an increasingly fast-paced, over-consuming society, we want to act humanely on our own scale. We therefore ask our factories to be transparent and honest with us. We are also committed to supporting associations such as 1% for the Planet (for the ADRET range) and Protect Our Winters. Other outdoor brands with whom we create partnerships must also respect our commitment to the environment. Finally, in our day-to-day work, we take action to reduce our carbon footprint on the environment.

EVERYDAY

We are committed to taking action in our day-to-day operations.

Insulating the premises was a necessary project to reduce our environmental impact. Insulation was reviewed and LED lights were installed to reduce our carbon footprint.

Every summer, ZAG undertakes to support and take part in a waste collection day in the Chamonix valley. Printing, advertising, goodies - every marketing action can pollute.

At ZAG, we're doing everything we can to reduce this pollution by printing on recycled paper, using recyclable/recycled substrates and doing DIY.